When a commercial fire is extinguished, a time-sensitive financial and operational emergency begins. For risk managers, underwriters, and insurance brokers, the actions taken in the first 24 hours are critical for mitigating loss and controlling the claim's trajectory. This guide outlines the strategic fire damage restoration steps required to stabilize the asset, prevent secondary damage, and execute a transparent and efficient recovery process.

A rapid, methodical response can dramatically reduce long-term costs, halt secondary damage like corrosion and mold, and establish a solid foundation for the insurance claim. The primary objective is to stabilize the asset and protect the financial interests of all stakeholders.

The First Response to a Commercial Fire Event

Safety is the non-negotiable first priority. Once the fire department declares the site safe for entry, the property must be secured immediately. This action transcends simply locking a door; it involves restricting all access to mitigate liability. The structure may be dangerously unstable, and invisible hazards like airborne soot and toxic particulates pose serious health risks.

Securing the Asset and Ensuring Safety

After a fire, a building's structural integrity is a primary and immediate concern. Intense heat can weaken steel beams, compromise concrete, and damage foundational supports. Before any personnel enter the premises, a qualified structural engineer must assess the building's stability. This is a mandatory step to ensure safety and compliance.

While awaiting the engineering assessment, the physical security of the site must be established. Key actions include:

- Boarding up windows and doors: This serves as the initial defense against unauthorized entry, vandalism, theft, and further damage from weather.

- Installing temporary fencing: A clearly defined perimeter prevents unauthorized access and helps manage site entry for essential personnel like adjusters and restoration crews.

- Disconnecting utilities: If not already performed by the fire department, gas, electricity, and water services must be shut off to prevent new hazards such as electrocution, gas leaks, or additional water damage from burst pipes.

In some cases, specialized drones for emergency response can provide a safe, immediate aerial assessment of roof and structural damage without endangering personnel. This technology offers a valuable preliminary overview of the damage scope.

Immediate Post-Fire Action Checklist

The first 24 hours post-fire represent a critical window for action. The following table outlines essential "dos" and "don'ts" for risk managers and property owners to protect the asset and facilitate a smoother claims process.

| Critical Action (Do) | Mistake to Avoid (Don't) | Impact on Claim and Recovery |

|---|---|---|

| Contact your insurer immediately to report the loss and receive initial guidance. | Don't delay notification. Waiting can complicate the claim and breach policy conditions. | Establishes the claim timeline and demonstrates proactive loss management. |

| Secure the property with professional board-up services and fencing. | Don't leave the site accessible to unauthorized individuals. | Prevents vandalism, theft, and liability for injuries, which can inflate claim costs. |

| Arrange for a structural assessment by a qualified engineer. | Don't allow anyone to enter before a structural engineer deems the building safe. | Prioritizes life safety and provides crucial data for the restoration scope and claim. |

| Mitigate further damage (e.g., water extraction, covering roof openings). | Don't assume the damage is "done." Soot and water cause progressive, costly issues. | Reduces overall loss, helps control claim costs, and accelerates the recovery timeline. |

| Document everything with photos and videos from a safe, designated distance. | Don't disturb, move, or discard anything before it is thoroughly documented. | Creates a vital, time-stamped record for the insurance adjuster and substantiates the claim. |

Executing these initial steps correctly demonstrates responsible risk management and provides a solid foundation for the entire recovery effort.

Mitigating Secondary Damage

While the fire is extinguished, the damage continues. Soot is highly acidic and begins to corrode and stain surfaces within hours. The significant volume of water used in firefighting creates an ideal environment for rapid mold proliferation and saturates structural materials, leading to warping and decay.

Immediate mitigation is essential. This is where professional fire damage restoration steps transition from securing the site to actively preventing further financial loss.

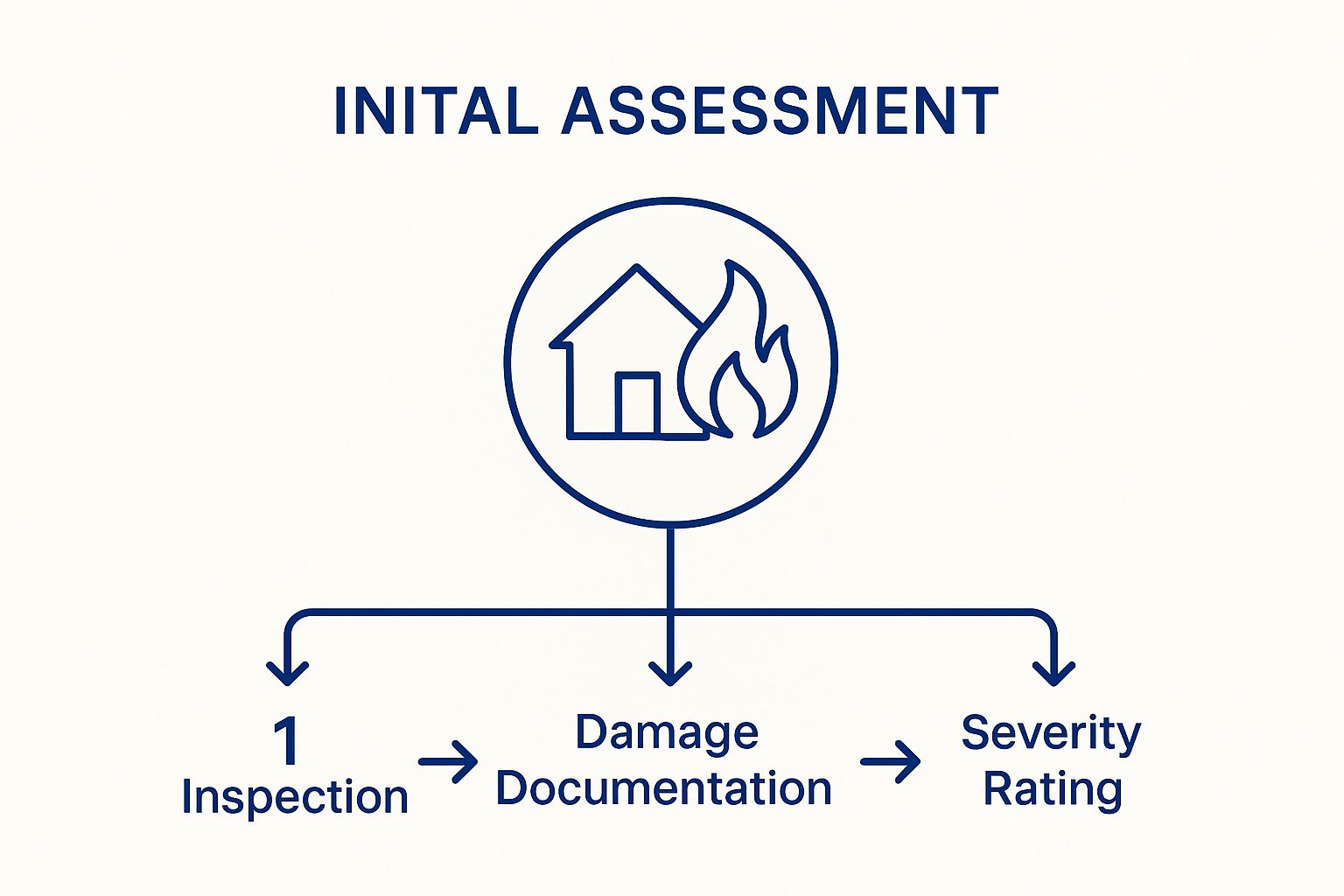

Image

This systematic approach ensures every vector of damage is identified and categorized. It forms the backbone of an effective restoration plan and an accurate, comprehensive insurance claim. The global fire damage restoration market, estimated at approximately $15 billion in 2025, is projected to grow at a CAGR of roughly 6% through 2033. This growth underscores the increasing complexity and critical nature of a professional response.

Executing the Damage Assessment and Claim Strategy

Image

Once the property is safe and secure, the forensic damage assessment begins. This is not a superficial walk-through; it is a detailed investigation that establishes the foundation for the entire insurance claim and restoration plan. An incomplete assessment invariably leads to disputes, underpayment, and extended business interruption.

For risk managers and brokers, this phase is a key opportunity to demonstrate value. The quality of this initial evaluation directly correlates with the final settlement amount. Every damaged asset, square foot of compromised structure, and hour of lost business must be meticulously documented.

Differentiating Damage Types for Accurate Reporting

Fire damage is multifaceted. To build a robust claim that aligns with policy coverages, the loss must be segregated into distinct categories.

Key loss categories include:

- Structural Damage: This pertains to the building itself, from the foundation and load-bearing walls to the roof, flooring, and integrated systems like HVAC and electrical. A trained expert must identify not only overt charring but also heat-weakened steel, compromised concrete, and smoke saturation within porous materials like drywall and insulation.

- Contents Damage: This category covers all non-structural assets within the building, including machinery, inventory, office furniture, electronics, and critical documents. Each item requires inventory and assessment: salvageable, total loss, or requiring specialized cleaning. Replacement or repair costs must then be determined.

- Business Interruption (BI) Loss: This assesses the financial damages from the inability to operate. Calculation involves projecting lost revenue and tallying ongoing expenses (e.g., payroll, rent) that continue despite the shutdown. A successful BI claim depends on accurate pre-loss financial records and a realistic recovery timeline derived from the structural and contents assessments.

A common oversight is focusing solely on direct fire damage. Secondary damage from smoke and water frequently constitutes a significant portion of the total loss. Smoke travels far beyond the fire's origin, corroding sensitive electronics and contaminating inventory, while water from firefighting efforts can destroy equipment and create conditions for widespread mold growth.

The Adjuster Decision: Public vs. Company

Early in the claim process, a critical strategic decision arises: whether to rely solely on the insurance company's adjuster or to engage a public adjuster. Understanding the roles is vital for any broker or risk manager advising a client.

An insurance company adjuster is employed by the insurer. Their role is to investigate the claim on behalf of their employer, determine the covered loss according to the policy, and propose a settlement. While professional, their fiduciary duty is to the insurance carrier.

A public adjuster is a state-licensed professional retained by the policyholder. Their fiduciary duty is 100% to their client. They manage the entire claims process—from documentation and valuation to direct negotiation with the insurer—with the objective of maximizing the policyholder's settlement.

For a complex commercial loss, engaging a public adjuster can be a strategic advantage. They provide deep expertise in policy interpretation and claims negotiation, which levels the playing field during high-stakes negotiations involving multi-million dollar losses and significant business interruption.

Best Practices for Forensic Documentation

Modern damage documentation requires a multi-layered, technology-driven strategy to build an indisputable claim file.

Effective documentation methods include:

- 3D Matterport Scans: These tools create immersive, virtual models of the property, producing an unchangeable digital twin of the post-fire conditions. Adjusters and estimators can conduct virtual walk-throughs, take precise measurements, and verify damage without repeated site visits.

- Thermal Imaging: Infrared cameras are essential for detecting moisture hidden within walls, ceilings, and floors. This is critical for identifying the full extent of water damage from firefighting efforts before it leads to mold.

- Detailed Inventory Logs: A simple list of contents is insufficient. A detailed spreadsheet should be created for every item, including its make, model, serial number, pre-loss condition, and estimated replacement cost. High-value items must be supported with photographic evidence.

Combining these methods produces a robust, evidence-based claim file that minimizes disputes and accelerates the settlement process. This level of detail in the fire damage restoration steps is what distinguishes a smooth recovery from a protracted conflict.

Advanced Soot and Smoke Remediation Techniques

Image

The fire itself is only the initial event. The most pervasive and lingering damage results from soot and smoke—corrosive, invasive substances that pose a significant long-term risk to the building's integrity and occupants' health.

These particulates travel far beyond the fire's origin, settling on every surface and penetrating deep into porous materials. For underwriters and risk managers, this is where a claim's cost can escalate. Differentiating between superficial cleaning and technical remediation is critical. Executing the correct fire damage restoration steps for smoke and soot is essential to prevent future liability claims and ensure a property is safe for re-occupancy.

Decoding the Types of Smoke Damage

Not all smoke damage is identical. The fuel source dictates the type of residue, and each requires a distinct remediation strategy. A one-size-fits-all approach is ineffective and can exacerbate the damage by smearing sticky residues or driving fine powders permanently into surfaces.

An experienced restoration professional will not begin cleaning until they have identified the type of smoke residue.

- Wet Smoke: Originates from low-heat, smoldering fires involving plastics and rubbers. The residue is sticky, smeary, and has a pungent odor, making it notoriously difficult to clean.

- Dry Smoke: Results from fast-burning, high-temperature fires consuming paper and wood. This residue is a fine powder. While easier to remove from hard surfaces, it penetrates every microscopic crevice.

- Protein Smoke: Common in restaurant kitchen fires, this residue from evaporated animal fats or proteins is nearly invisible but creates a powerful, foul odor and can permanently discolor paints and varnishes if not treated properly.

- Fuel Oil Smoke: Caused by furnace puff-backs or petroleum-based fires. This residue is dense and sticky, requiring specialized solvents for effective breakdown.

A restoration contractor's proposal that fails to specify the smoke type and a corresponding cleaning methodology should be considered a significant red flag, indicating a potential lack of technical expertise.

Matching Technology to the Task

Once the smoke type is identified, appropriate technology must be deployed. This is a key differentiator between professional remediation and standard cleaning services. When reviewing a restoration proposal, look for specific technologies chosen to address the specific residue.

Selecting the right remediation technology is about efficacy, not cost-cutting. Using an incorrect method, such as applying wet cleaning to dry smoke residue, can convert a removable powder into a permanent stain, significantly increasing the claim's cost and scope.

The damage restoration industry in the United States is projected to reach $7.1 billion in revenue in 2025, driven largely by the increasing technical demands of catastrophic events like wildfires. This growth reflects a market shift toward specialized expertise. For more market data, explore insights on the damage restoration services industry.

HVAC Decontamination: A Non-Negotiable Step

HVAC system contamination is a frequent point of failure in restoration projects. As the building's circulatory system, it inhales smoke and soot during a fire, distributing these hazardous particulates to all areas—even those untouched by flames.

Neglecting the HVAC system guarantees project failure. The moment the system is reactivated, it will re-contaminate the entire, newly cleaned building with soot and persistent odors.

Proper HVAC decontamination is a meticulous process:

- System-Wide Inspection: Professionals use specialized cameras to inspect the entire length of the ductwork.

- Specialized Cleaning: This involves using high-powered vacuums, agitators, and air whips to dislodge and capture soot from deep within the system.

- Component Cleaning: The air handler, coils, and blowers must be manually cleaned and sanitized.

- Filter Replacement: All filters must be replaced with new, appropriately rated units.

Omitting a thorough HVAC cleaning constitutes an incomplete job, poses a direct health risk to future occupants, and is a certain cause of future complaints and potential claims. It is an essential component of any competent fire damage restoration process.

Mastering Water Damage and Structural Drying

When fire suppression activities conclude, a second, less visible crisis begins: catastrophic water damage. The thousands of gallons of water used to extinguish the flames now pose a significant threat to the building's structural integrity. For underwriters and adjusters, proficiently managing this phase is a direct lever for controlling claim costs and accelerating business recovery.

This is not a simple "mop-up" operation. It is a critical component of the fire damage restoration steps that must run in parallel with soot and smoke remediation. Aggressive water removal and structural drying are mandatory to prevent a cascade of more severe and costly problems.

First, Get the Water Out—Fast

The damage from water begins immediately. There is a 24- to 48-hour window before microbial growth and material degradation accelerate significantly. Standing water, whether from fire hoses or sprinkler systems, saturates everything it contacts. The immediate priority is high-volume water extraction.

Professional restoration teams deploy heavy-duty equipment—powerful, truck-mounted and submersible pumps—to remove bulk water as rapidly as possible. This initial de-watering is non-negotiable for several reasons:

- It halts material saturation. The longer materials like drywall, wood framing, and subfloors remain submerged, the more water they absorb, leading to irreversible swelling, warping, and delamination.

- It reduces ambient humidity. Standing water evaporates, increasing interior humidity levels. This creates a humid environment ideal for mold growth and can damage sensitive electronics and machinery untouched by the fire.

- It enables the drying process. A building cannot be effectively dried while it contains standing water. Extraction is the essential first step.

The Science of Structural Drying

Once standing water is removed, the science of structural drying begins. This process is governed by psychrometrics—the scientific study of the properties of moist air. The objective is to create an engineered environment that actively pulls moisture from wet materials and then physically removes that moisture from the building.

This is achieved by deploying two key types of industrial equipment in a coordinated manner:

- Industrial Air Movers: These are not standard fans but high-velocity centrifugal blowers positioned to create a vortex of air that flows directly across wet surfaces like floors and walls. This powerful airflow accelerates evaporation, drawing moisture from within materials into the air.

- Low-Grain Refrigerant (LGR) Dehumidifiers: These machines are the core of a professional drying operation. As air movers release moisture into the air, LGR dehumidifiers draw in this humid air. They cool it over refrigerated coils, condensing the water vapor for collection. They then exhaust warm, extremely dry air back into the space. This process progressively lowers the overall humidity, enabling the air to absorb more moisture from the structure.

A common error is increasing the heat in an attempt to "bake" the building dry. This approach is counterproductive, as it creates a hot, humid environment—ideal for aggressive mold growth—without actually removing the moisture from the structure. Proper drying requires a precise balance of airflow, dehumidification, and temperature control.

Proving It’s Dry

The completion of the drying process is determined by data, not guesswork. Professionals use calibrated moisture meters and thermal imaging cameras to take continuous readings from all affected materials.

A "dry standard" is established by measuring the natural moisture content in an unaffected area of the building. This value becomes the target. Equipment is then adjusted and progress is monitored until every affected area—including those inside wall cavities and beneath floors—meets this dry standard.

This meticulous documentation is also crucial for preventing secondary damage. Rapid and thorough water removal halts mold before it can establish itself. Knowledge of related processes, like effective grout cleaning strategies to halt mold growth in specific areas, contributes to a holistic restoration plan. For an underwriter, a detailed drying log with documented moisture readings provides verifiable proof that the job was executed correctly, dramatically reducing the risk of a future mold-related claim.

Final Cleaning, Sanitization, and Odor Removal

Once the structure is dry and soot has been remediated, the final phase begins: returning a damaged property to a safe, clean, and odor-free state. For insurance professionals, this stage is critical. Signing off on these final fire damage restoration steps is about eliminating latent health risks and preventing future complaints, such as the return of smoke odor.

Cutting corners in this phase almost guarantees a reopened claim. The first humid day can reactivate dormant smoke odors, eroding policyholder satisfaction.

Specialized Cleaning for Salvageable Contents

Many high-value contents, from industrial machinery to sensitive textiles, can be salvaged with specialized technology rather than being written off as a total loss.

- Ultrasonic Cleaning: This method is ideal for hard, non-porous items with intricate surfaces, such as tools, machine parts, or delicate collectibles. Items are submerged in a tank with a specialized cleaning solution and subjected to high-frequency sound waves. This creates millions of microscopic, imploding bubbles (a process called cavitation) that effectively blast away soot from the tightest crevices without causing abrasive damage.

- Esporta Wash Systems: For soft goods like uniforms, bedding, or personal protective equipment, advanced hydraulic washing systems are highly effective. An Esporta machine uses a combination of hydraulic pressure and proprietary detergents to physically force contaminants out of fabric. This process is proven to remove over 99% of bacteria and soot, restoring items that would otherwise be declared a total loss.

Awareness of these technologies enables adjusters and brokers to make more cost-effective claim decisions. Restoring high-value items is almost always more economical than outright replacement.

Going Beyond Masking to Truly Eliminate Odors

A common failure in fire restoration is the inadequate elimination of odors. Spraying a deodorizer only provides temporary masking. True professional deodorization involves chemically altering the odor-causing molecules to permanently eliminate them.

The smell of smoke is more than a nuisance; it is a persistent psychological reminder of the traumatic fire event for the property owner. Permanent odor removal is a non-negotiable component of a complete business recovery.

The demand for comprehensive restoration is growing. The U.S. fire damage restoration market is projected to increase from $8 billion in 2025 to $15 billion by 2033. This growth is driven by a rise in catastrophic events like wildfires and a clear understanding within the insurance industry that thorough, professional execution up front streamlines claims and prevents long-term liabilities. You can learn more about the rising demand for these services and its market impact.

Advanced Odor Neutralization Technologies

To achieve permanent results, restoration professionals deploy equipment that actively destroys odor molecules.

| Technology | How It Works | Best Use Case |

|---|---|---|

| Ozone Shock Treatment | An ozone generator floods a sealed, unoccupied space with O3 gas. The highly reactive third oxygen atom detaches and oxidizes odor molecules on contact, neutralizing them. | Extremely effective for powerful, deep-set odors throughout an entire structure. The space must be completely unoccupied during treatment due to health risks. |

| Hydroxyl Generation | A hydroxyl generator uses UV light to create hydroxyl radicals (·OH), which are nature's own highly reactive "scrubbers." They safely break down odors and VOCs in the air and on surfaces. | A safer alternative to ozone that can be used while crews are working. Ideal for continuous deodorization throughout the project. |

| Thermal Fogging | A specialized deodorizing agent is heated to create a fine, dry "fog." This fog mimics the behavior of smoke, penetrating deep into porous materials like wood and drywall to neutralize embedded odor particles. | The most effective solution for tackling odors that have deeply penetrated porous structural materials and furnishings. |

Finally, as a non-negotiable final step, a professional air duct cleaning is essential. This ensures any residual soot and smoke particles are removed from the HVAC system, preventing re-contamination of the clean space.

Getting to the Finish Line: The Reconstruction Phase

This is the culmination of all preceding efforts. After the site has been secured, cleaned, and stabilized, the reconstruction phase restores the property to its pre-loss condition or better. It is the final and often most complex part of the recovery, transforming a prepared site back into a fully operational facility.

<iframe width="100%" style="aspect-ratio: 16 / 9;" src="https://www.youtube.com/embed/SNRJR89HNP8" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>

For risk managers and brokers, this is not merely a construction project; it is the final validation of the entire claim. The objective is to confirm that the work aligns with the policy, meets the client's operational needs, and properly closes out all previous fire damage restoration steps.

The Critical Handoff from Mitigation to Rebuilding

A common point of failure in large-loss projects is the handoff from the mitigation/restoration company to the general contractor.

The restoration team possesses critical intelligence, including identified hidden structural damage, areas of persistent moisture, and a complete record of all chemical agents used for cleaning and sanitization. If this information is not effectively transferred to the builder, it can lead to serious errors, rework, and costly delays.

The solution is a formal handover meeting. All key stakeholders—the property owner, risk manager, insurance adjuster, restoration project manager, and general contractor—must convene. The agenda is to review every mitigation report, drying log, and decontamination certificate before any new building materials are brought on site.

Building Back Better: Compliance and Resilience

Reconstruction is rarely about simply restoring a property to its previous state. Building codes are continuously updated, and a major fire often legally mandates that the repaired structure adhere to the latest standards. This can necessitate significant upgrades to electrical systems, fire suppression, and structural components.

This phase presents a prime opportunity for a risk manager to deliver significant long-term value. By advocating for fire-resistant materials and improved design during the rebuild, you can directly influence future insurance premiums and substantially lower the property's overall risk profile.

This opportunity should be leveraged to implement strategic upgrades:

- Fire-Resistant Building Materials: Specify Class A-rated roofing, non-combustible siding such as fiber cement, and fire-rated gypsum board in critical areas.

- Upgraded Fire Suppression: This is the ideal time to install a modern sprinkler system or upgrade an existing one to meet current NFPA standards.

- Defensible Space: For properties in wildfire-prone regions, redesigning the landscaping to create a buffer zone free of flammable vegetation is one of the most effective loss prevention strategies.

These actions are not merely repairs; they are investments in resilience, turning a catastrophic event into a clear opportunity to create a stronger, safer, and more insurable asset.

The Final Walkthrough and Project Sign-Off

The project is not complete until the final walkthrough is concluded. This is a detailed inspection, using the approved scope of work as a checklist, to create a final punch list.

All stakeholders should participate, methodically comparing the finished product against the agreed-upon plans. This is the last opportunity to identify any deficiencies, from minor cosmetic issues to functional discrepancies.

Once all parties agree that the work is completed to standard, a Certificate of Completion is signed. This legal document signifies the end of the project. It formally closes out the claim, confirms the property is safe and fully restored, and signals that the business is ready for re-occupancy. The recovery journey is officially complete.

Common Questions About Fire Damage Restoration

Image

During the initial assessment of a fire-damaged property, several key questions consistently arise. For insurance professionals and commercial property owners, obtaining clear, data-driven answers is fundamental to managing expectations and initiating an effective recovery plan.

One of the first questions is, "How long will this take?" While there is no universal answer, a typical commercial fire damage restoration project can range from several weeks to many months. The timeline is dictated by measurable factors: the severity of the fire, the extent of water damage, and the complexity of reconstruction required to meet current building codes.

Differentiating Salvageable and Non-Restorable Items

The decision of what to salvage versus what to discard is a calculated assessment based on several key factors relevant to adjusters and contractors.

- Item Composition: Porous materials—such as untreated wood, drywall, insulation, and textiles—absorb smoke and soot at a molecular level, making complete restoration often unfeasible. Conversely, non-porous items like metal and glass have a much higher probability of being successfully restored.

- Cost-Effectiveness: The analysis comes down to a "repair versus replace" calculation. If the cost of professional restoration, including specialized cleaning and deodorization, exceeds an item's replacement value, it is classified as a non-salvageable loss. This is a matter of pure economics.

- Level of Contamination: Safety is the overriding factor. Items exposed to hazardous materials during the fire or those with extensive mold growth from water damage are often too dangerous to restore and must be properly disposed of as part of the claim.

Managing client expectations regarding what can be realistically salvaged is a critical function of the claims process. A transparent evaluation based on these criteria prevents disputes and justifies the costs associated with both restoration and replacement, providing a clear and defensible path forward in the overall fire damage restoration steps.

Understanding these distinctions allows brokers and adjusters to clearly articulate the rationale behind claim decisions, fostering trust and clarifying the recovery strategy for all stakeholders. It is about making informed choices that prioritize safety and financial prudence.

---

Turn climate disasters into actionable business opportunities. Sentinel Shield delivers verified, high-intent leads from businesses impacted by wildfires, storms, and floods directly to you within 24 hours. Stop chasing cold leads and start connecting with clients at their moment of need. Discover how our real-time climate intelligence can fuel your growth.